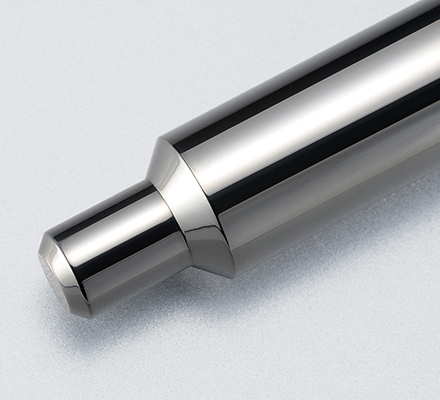

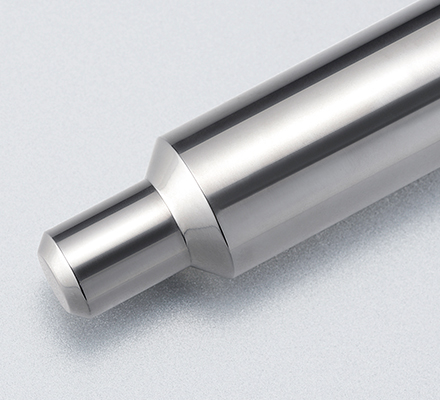

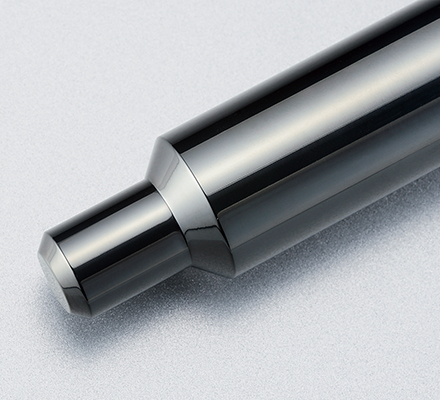

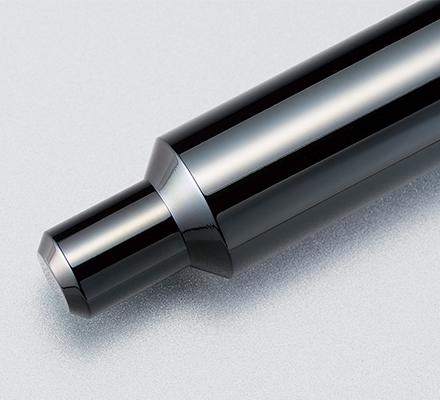

Coating Film

Y-coat variation

We offer 11 types of coatings and composite treatments to provide the functions lacking in the mold material itself, depending on the application.

-

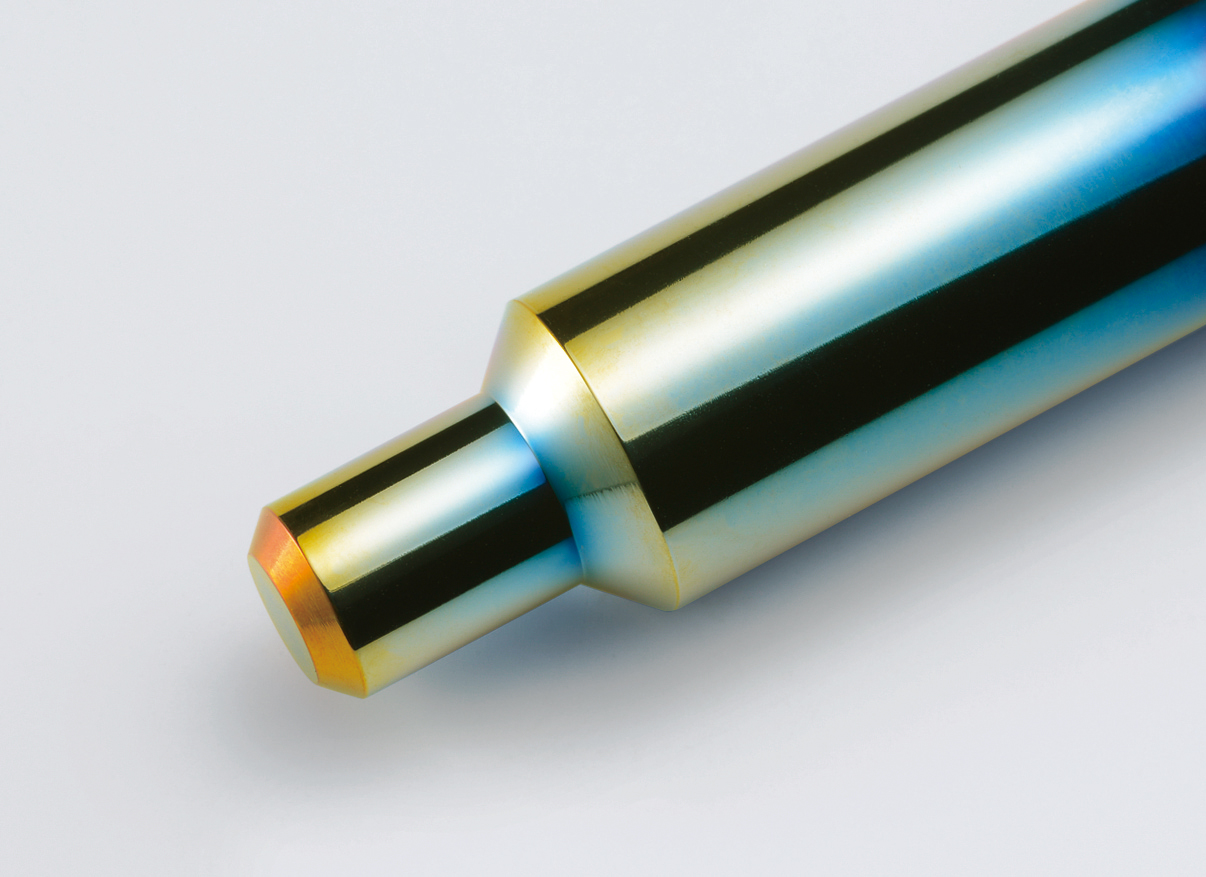

Type N (TiN)

Excellent abrasion and seizure resistance

Excellent abrasion and seizure resistance- Application

- Cold forging and pressing

- Film thickness

- 2μm

- Hardness

- 2,200 Hv

- Oxidation temperature

- 400℃

-

Type CN (TiCN)

Excellent wear resistance due to TiN and TiCN layered film

Excellent wear resistance due to TiN and TiCN layered film- Application

- Cold forging and pressing

- Film thickness

- 2μm

- Hardness

- 2,800 Hv

- Oxidation temperature

- 300℃

-

Type R (CrN)

Excellent weldability, slipperiness, and heat resistance

Excellent weldability, slipperiness, and heat resistance- Application

- Cold forging, press, warm and hot forging, die casting

- Film thickness

- 5μm

- Hardness

- 1,800 Hv

- Oxidation temperature

- 600℃

-

Type C (Cr base)

Excellent weldability and heat resistance

Excellent weldability and heat resistance- Application

- Warm and hot forging and die casting

- Film thickness

- 7μm

- Hardness

- 2,200 Hv

- Oxidation temperature

- 800℃

-

Type V (V base)

High hardness film and excellent abrasion resistance

High hardness film and excellent abrasion resistance- Application

- Cold forging and pressing

- Film thickness

- 3μm

- Hardness

- 3,300 Hv

- Oxidation temperature

- 400℃

-

Type G (V base)

Excellent weldability, slipperiness, and abrasion resistance due to high smoothness

Excellent weldability, slipperiness, and abrasion resistance due to high smoothness- Application

- Pressing

- Film thickness

- 3μm

- Hardness

- 3,500 Hv

- Oxidation temperature

- 400℃

-

Type AⅡ (AI base)

Excellent galling resistance due to high heat resistance

Excellent galling resistance due to high heat resistance- Application

- Cold forging and pressing

- Film thickness

- 3μm

- Hardness

- 3,500 Hv

- Oxidation temperature

- 1,200℃

-

Type BL

Excellent abrasion resistance, mold release, and corrosion resistance due to high hardness and high water repellency

Excellent abrasion resistance, mold release, and corrosion resistance due to high hardness and high water repellency- Application

- Plastic molding

- Film thickness

- 1μm

- Hardness

- 2,500 Hv

- Oxidation temperature

- 500℃

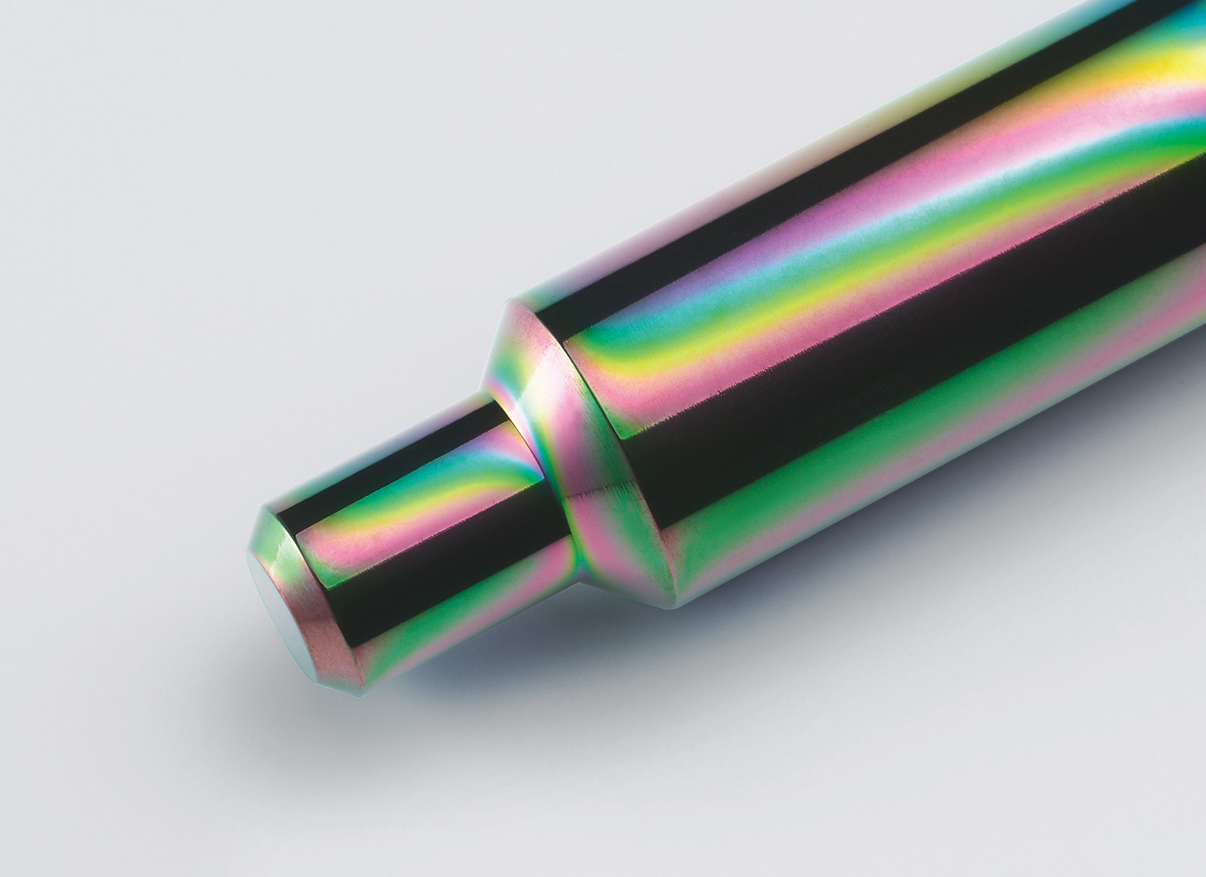

Type YA

-

YA0.1

Excellent weldability and slipperiness

- Application

- Nonferrous (aluminum, copper) forging and pressing

- Film thickness

-

0.1um

- Hardness

-

6,000~7,000Hv

- Oxidation temperature

-

500℃

-

YA0.5

Excellent weldability and slipperiness

- Application

- Nonferrous (aluminum, copper) forging and pressing

- Film thickness

-

0.5um

- Hardness

-

6,000~7,000Hv

- Oxidation temperature

-

500℃

-

YA1.0

Excellent weldability and slipperiness

- Application

- Nonferrous (aluminum, copper) forging and pressing

- Film thickness

- 1.0um

- Hardness

-

6,000~7,000Hv

- Oxidation temperature

- 500℃

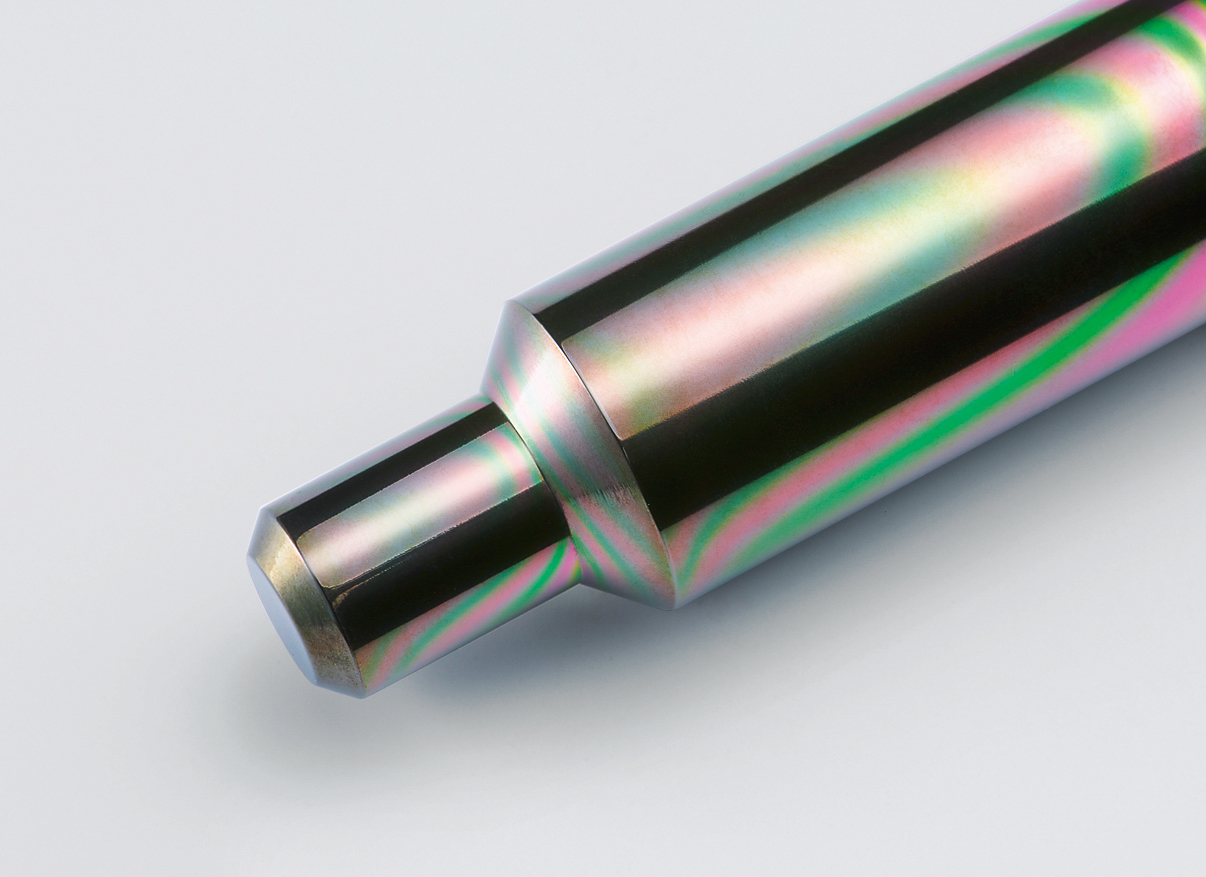

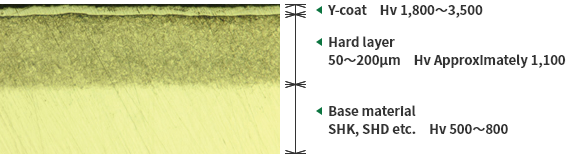

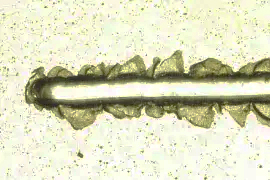

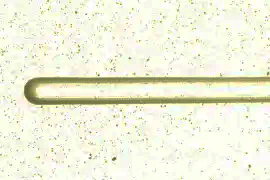

Type K + Y-coat treatment

This is a composite treatment in which a hardening treatment (Type K) is applied to the metal material and Y-coat is applied on top of it.

The synergistic effect of “material hardening + Y-coat” provides an effect greater than that of conventional ion plating coatings.

Cross-section of film

Features

- Greater abrasion and galling resistance, softening resistance, fatigue resistance, etc.

- Dimensional changes are also the same as for Y-coat only.

Precautions

- Materials such as stainless steel, cemented carbide, etc., for which the hardened layer is difficult to diffuse, may not be sufficiently effective.

Abrasion and galling resistance

Y-coat only

Type K + Y -Coat

The hardening of the base metal surface layer makes it difficult for foreign matter and burrs to penetrate. Also, since the deformation of the base metal due to penetration is minimized, the coating film can easily follow and the chipping breakdown of the film is reduced.

Flowchart for Y-coat application

- Application

- Damage form

- Y-coat film type

-

Cold forging

-

Galling and abrasion

Type N(TiN)・Type CN(TiCN)・Type V・Type AⅡ・Type G -

If severe

Type K + Type N(TiN)・Type CN(TiCN)・Type V・Type AⅡ・Type G -

Welding and seizure

Type R(CrN)・Type AⅡ -

Cracking

Change of mold material + Type R(CrN)

-

-

Press

-

Galling and abrasion

Type N(TiN)・Type CN(TiCN)・Type V・Type AⅡ・Type G -

If severe

Type K + Type N(TiN)・Type CN(TiCN)・Type V・Type AⅡ・Type G -

Welding and seizure

Type R(CrN) -

Cracking

Change of mold material + Type R(CrN)

-

-

Die casting

-

Welding and seizure

Type R(CrN)・Type C -

Abrasion

Type K + Type R(CrN)・Type C -

Heat rack

Change of mold material + Type R(CrN)・Type C

-

-

Warm and hot forging

-

Abrasion

Type K + Type C -

Heat rack

Change of mold material + Type R(CrN)・Type C

-

-

Resin

-

Poor mold release

Type BL plus -

Corrosion and stain resistance

Type BL -

Abrasion

Type BL・Type CN

-

Inquiries about TL Division